SMA Mineral - A world full of lime

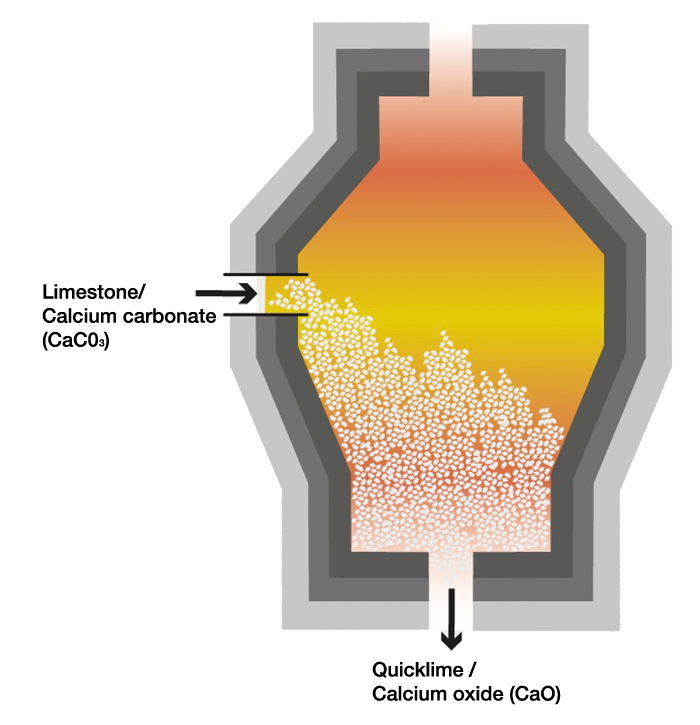

Our basic minerals, limestone and dolomite, can be further processed through burning or slaking. These processed products acquire different physical and chemical properties and entirely new applications.

Quicklime

Slaked Lime

Burnt Dolomite

Mesa

Mesa can be recovered by re-burning it into burnt lime and then reusing it in the pulp mills.

SMA Mineral AB

Box 329

682 27 Filipstad

SWEDEN