The reactivity and high purity of lime make it a sought-after option for flue gas purification. Both quicklime and slaked lime are essential consumables in the industrial and energy sectors. A major consumer of lime is the combined heat and power plant Händelöverket in Norrköping, which has been using large volumes of SMA Mineral's lime products in its flue gas purification processes since this spring.

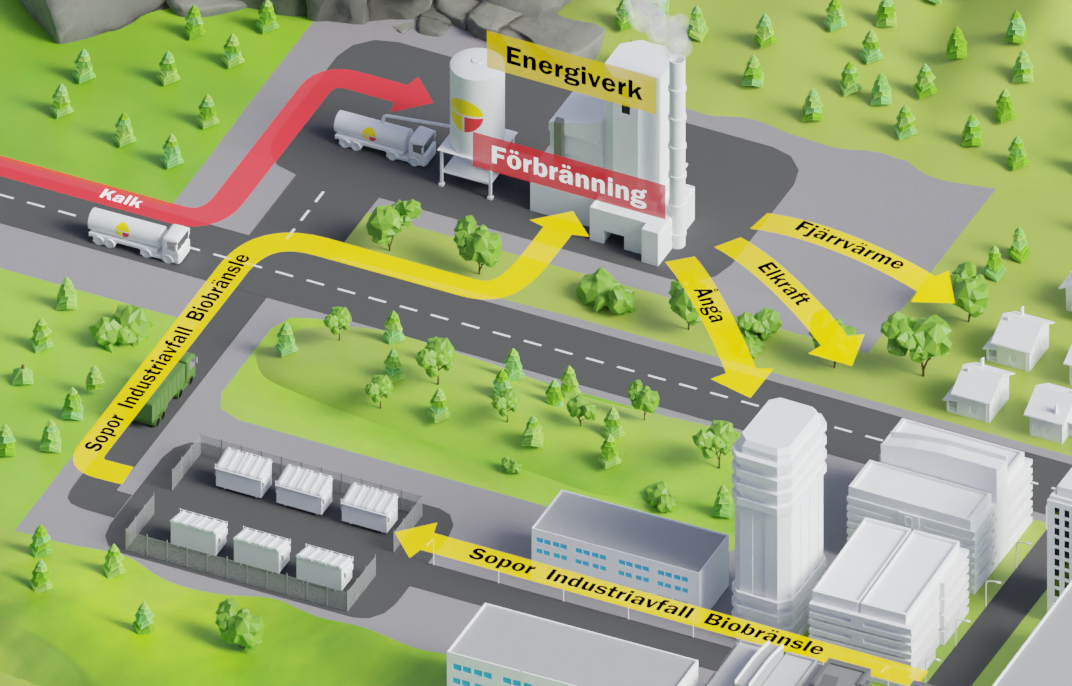

Händelöverket in Norrköping is one of Sweden’s largest combined heat and power plants. The facility, owned and operated by the energy company E.ON, produces district heating, electricity, and process steam for customers throughout the Norrköping region.

– In our boilers, we burn household and industrial waste as well as biofuels such as forest chips and reclaimed wood," says the plant’s production manager, Mattias Redeborn. "Energy from Händelö serves customers in the urban areas of Norrköping and Söderköping, as well as the area north of Norrköping up toward Åby. In total, more than 1,600 GWh is produced annually.

Lime for Flue Gas Purification

During combustion in the plant’s boilers, flue gases are generated that must be purified from harmful substances before being released into the atmosphere. The purification process involves using lime-based products to neutralize and precipitate pollutants before they exit through the chimney.

– We use several methods—dry, semi-dry, and wet—to purify the condensate, explain process engineer Sara Bergqvist and operations manager Jesper Casperson. All of them require some form of lime.

The purification processes use quicklime, slaked lime, limestone flour, and dolomite.

– We purchase and store both quicklime and slaked lime, continue Sara and Jesper. To some extent, we also slake the quicklime ourselves by adding water.

Lime is primarily needed to bind acidic components, such as hydrochloric acid and sulfuric acid, from the flue gases.

Extensive Testing

Händelöverket is one of four combined heat and power plants owned by E.ON in Sweden. The others are located in Stockholm, Örebro, and Malmö.

– Since 2019, our facility in Stockholm has been sourcing its lime from SMA Mineral," says Sofia Borg, Category Manager for Additives at E.ON. "The collaboration has worked well, which led to the decision to test SMA Mineral’s products in Norrköping as well.

The tests began early in the spring, and in May, the decision was made to continue the partnership.

– The tests were extensive and placed high demands on SMA Mineral, continues Sofia Borg. During the testing period, we required almost daily lime deliveries, which were handled flawlessly. We also felt that SMA Mineral’s staff, led by Jarek Fastlind, were fully committed during the tests and provided the service we needed.

The quality of the lime was also carefully evaluated.

– There is no doubt that there is both good and bad lime, notes Sara Bergqvist. From our perspective, we have specific requirements regarding how the lime fractures during slaking as well as its hardness. Hard lime causes more wear on tools and equipment.

Large Volumes

Since the decision was made, full-scale deliveries have been ongoing. Typically, at least one truckload arrives in Norrköping every week. The lime is transported in bulk by truck and transferred into large silos for storage.

The volumes are significant. E.ON’s total purchases from SMA Mineral—for both Stockholm and Norrköping—are expected to reach approximately 6,000 tons of quicklime and 150 tons of slaked lime this year.

Environmental Focus

For E.ON, as well as other energy companies, environmental issues are central.

– Emission regulations are constantly tightening, as are the requirements for the landfills where the ash from our facilities is deposited," says Jesper Casperson. "This indirectly affects our suppliers as well.

Operations Manager Mattias Redeborn shares this perspective.

– We closely monitor the carbon footprint of our own processes, but we also evaluate the sustainability efforts of our suppliers. We are aware of SMA Mineral’s involvement in ZEQL and appreciate their active efforts to reduce CO2 emissions.