Quality control is a crucial step in our supply chain. Customers should feel confident that the delivered materials have been tested and meet the promised specifications.

Our facilities take daily samples of materials scheduled for delivery and send them to the laboratory, where they are processed, analyzed, and returned.

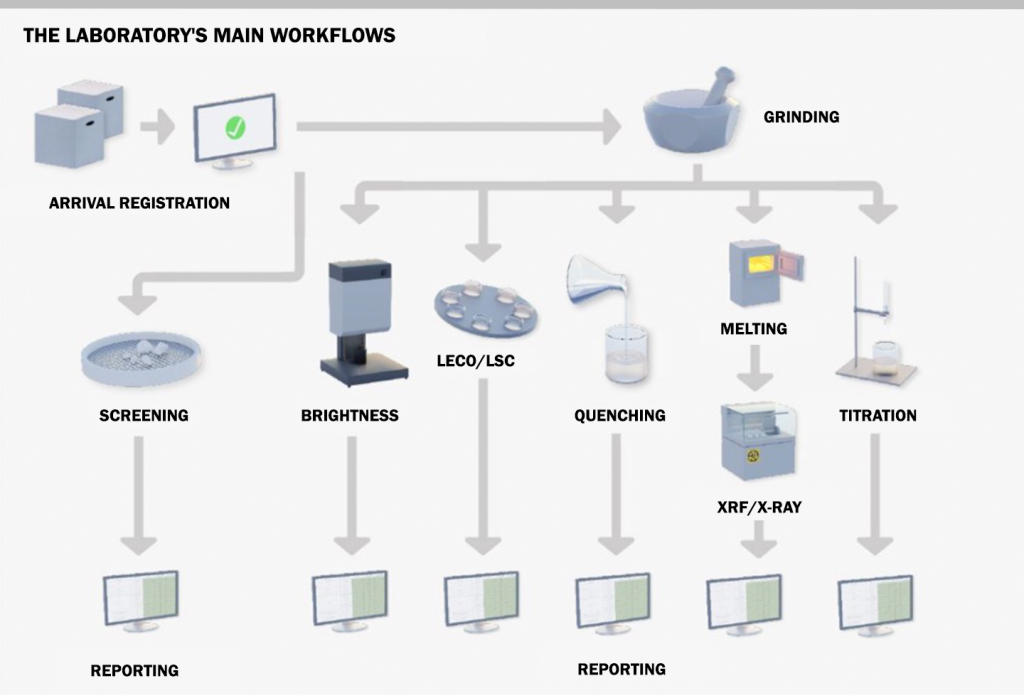

Over the years, the lab has developed efficient and reliable testing routines. The process follows a structured sequence, from incoming inspection and registration to the final lab report, which is sent back to the sample provider once testing is complete.

To analyze material properties, minerals are ground as a preparatory step before analysis. The tests are then carried out using multiple methods. Some materials undergo titration, while others are tested using Leco/LSC methods. We also use XRF technology (X-Ray Spectroscopy) to measure specific elemental compositions.

In addition to quality testing, the laboratory has other responsibilities. Through collaboration with the marketing department and our site managers, signals regarding desired product improvements are identified and interpreted. Feedback and suggestions received serve as the foundation for continuous product development.

Alongside the lab, SMA Mineral’s technical team is also actively involved in this process.

SMA Mineral AB

Box 329

682 27 Filipstad

SWEDEN